OEM/ODM CNC Machining/Machinery/Machined Die Casting/Steel Casting Stainless Steel/Copper Alloy/Aluminum Alloy/Brass Turning/Milling Spare Metal Parts

Package size per unit product 29.00cm * 8.00cm * 11.00cm Gross weight per unit product 1.900kg OEM Die Casting Supplier

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | QY-CNC-1246 |

| Machining | Die Casting |

| Material | Aluminum Alloy |

| Surface Preparation | Spray Coating |

| Pressure Chamber Structure | Horizontal |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 2 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008 |

| Tolerance | +/-0.005 - 0.01mm |

| Heat Treatment | Hardened and Tempered |

| Type of Manufacturing | OEM/ODM |

| Lead Time | 5-30days Depends on Quantities |

| Transport Package | Packing |

| Specification | Customer′ s 3D Drawings or Samples |

| Trademark | QY Precision |

| Origin | China |

Packaging & Delivery

Package size per unit product 29.00cm * 8.00cm * 11.00cm Gross weight per unit product 1.900kgProduct Description

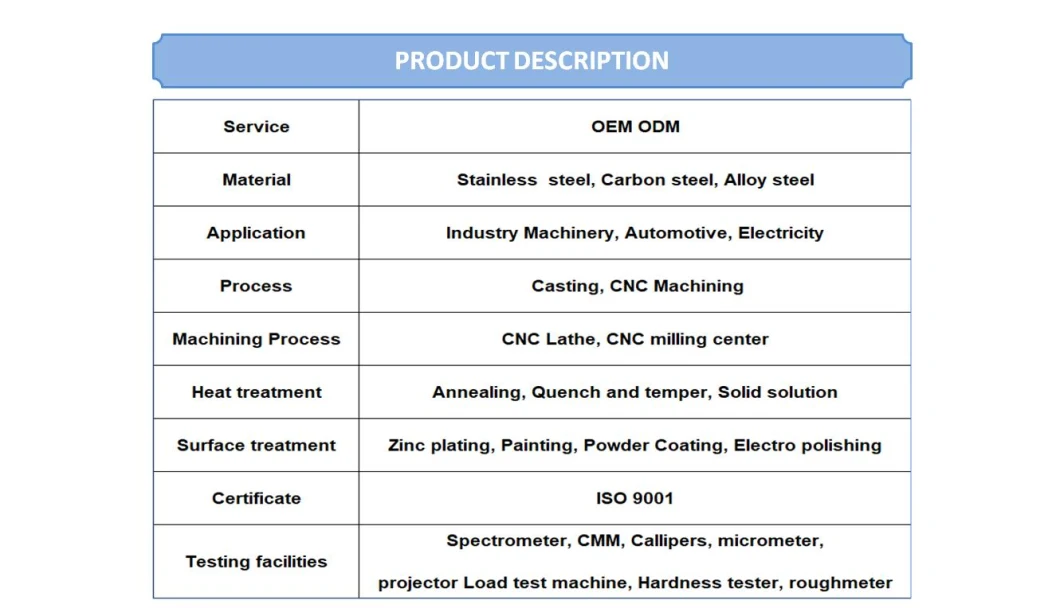

OEM Die Casting Supplier Professional Foundry of Casting Carbon Steel/Alloy Steel/ Stainless Steel/Iron/Aluminium Parts Sand/Wax-Lost/Gravity/Investment Casting

| Business Type | Manufacture |

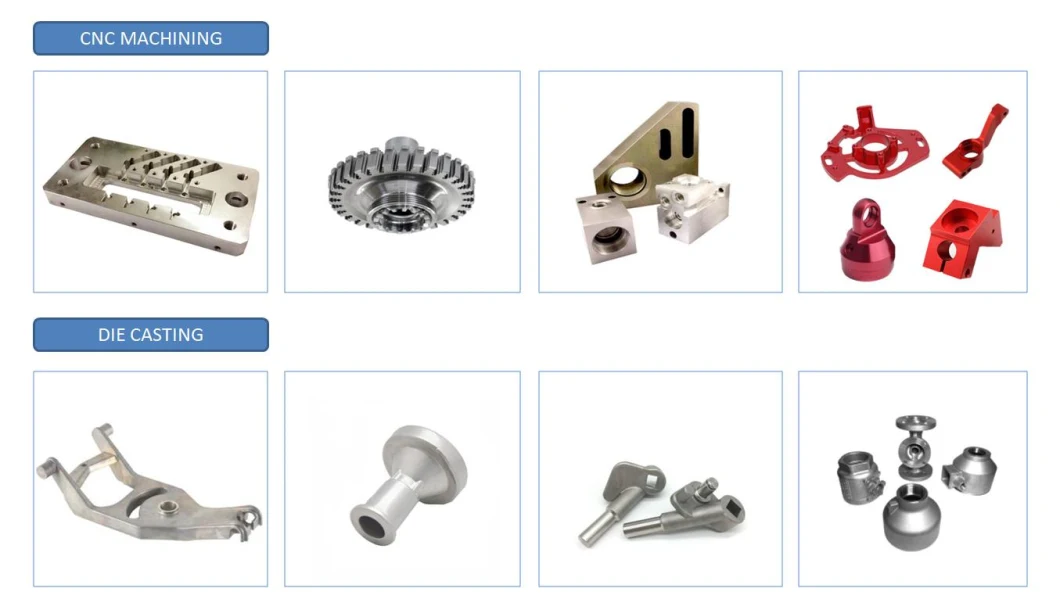

| Key words | CNC machining parts, precision CNC parts, CNC turning parts, CNC milling parts, metal parts, CNC parts, CNC machinery parts, Mechanical components, auto parts. Die casting parts, Metal stamping parts, sheet metal fabrication. |

| Materials | Aluminum, stainless steel, brass, copper, carbon steel, plastic (POM, PVC, PEEK, PU etc), alloy steel, titanium, Iron, spring steel, bronze. |

| Processing | CNC machining, CNC lathe/turning, 3/4/5 axis CNC milling, wire-cutting, EDM, grinding, Drilling, tapping etc. |

| Surface treatment | Anodized, passivation, heat treatment, painting, power coating, black oxide, silver/gold plating, electrolytic polishing, nitrided, phosphating, sandblasting, nickel/zinc/chrome/TiCN plated. |

| Application Industry | Aerospace, automotive, medical, telecommunications, electronic, packing, sensors, optical instruments, computers, motorcycles, bicycles,scooter etc. |

| Quality control | 100% full inspection for small QTY, ISO sampling inspection for mass productions. |

| Max Tolerance | +/- 0.001mm |

| Certificates | ISO9001:2015 |

| Lead Time | 1.Samples delivery:5-7 working days 2.Orders delivery:15-20 working days |

| Shipping Terms | 1) 0-500kg: express & air freight priority (DHL, FedEx, UPS, NTN) 2) >500kg: sea freight priority 3) As per customized specifications |

| Packing | Bubble wrap/pearl wool + Carton or Pallet; As per customized specifications |

| Sea Port | Guangzhou/Shenzhen/Hong Kong |

| Payment terms | T/T in advance, PayPal or Western Union is acceptable. |

| Trade Terms | EXW, FOB, CIF, As per customer's request |

| Drawing format | PDF, DWG, CAD, DXF, STEP, IGS etc |

| Note | All cnc machining parts are custom made according to customer's design drawings or exsiting samples, we have no any ready parts in stock for sales. If you have any cnc machining parts need to be made, please feel free to send your kind drawings/samples to us. |

Product Show

Our advantage

1. Focus on the customization of high-end zinc aluminum alloy die castings for Decades years2. We are a one-stop manufacturer integrating mold design, product die-casting, and surface treatment3. One-stop production, fast delivery, and the qualified rate of quality reaches 100%4. One-stop production, from product mold design to product surface treatment, perfect quality control5. Die-casting machines keep working 24 hours a day, with a daily output of 20W pieces, so we are capable of large quantity order6. Strictly implement the national quality standards of the die-casting industry, strictly implement the ISO9001-2015 quality management system, and the products have passed ROHS certification7. The quality is controllable, and the on-time delivery rate is 100% if there is no unstoppable disaster.8. More than 5000+ die-casting mold customization experience, support customized processing with drawings and samples

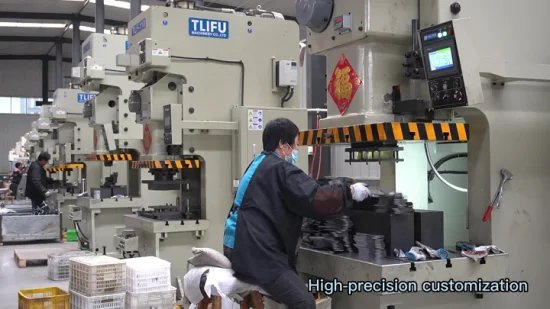

CNC Processing Ability We have a large number of machines to meet Turning/Milling/Drilling/Stamping etc. different processing, such as CNC machining center 3-Axis, 4-Axis and 5-Axis, CNC lathe machine, CNC automatic lathe machine, Punching machine, grinder, precision internal/external grinding, wire cutting, spark machine, etc. The detection equipment: projector, altimeter, digital micrometer, digital caliper, quick gauge, plug gauge, internal/displacement gauge and other high-precision testing instruments, the detection accuracy up to 0.001mm.

FAQ1.How to get a quote?Kindly send us the drawing of your product,please. Including details as below: a.Materials b. Surface Finish c. Tolerance d. Quantity If you need solutions for your application, kindly send us your detail requirements, and we will have engineers to serve you.2.How does the payment process work?Payment terms are flexible for us. We can accept different type payment way, for example: T/T3.How do I know about the production?We will double confirm your requirements and send you the sample before the mass production as you required. 4.How do I know about the delivery?Before shipment we will confirm with you about all the details including CI and other attention issues. After ship out, we will inform you of the tracking number and keep updating the latest shipping information for you.5.What will you do for after sales?We will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help. And welcome to contact for any supporting of your other application even if their is no relationship with our products.

6. Are you manufacturer or trader?Both trader and manufacturer. We have our own Machining factory, and also work with excellent factories to supply more process service to meet cutomers' requirements.

Related Products

-

![Professional Manufacturer Brass Copper CNC Turning Milling Machining Parts]()

Professional Manufacturer Brass Copper CNC Turning Milling Machining Parts

-

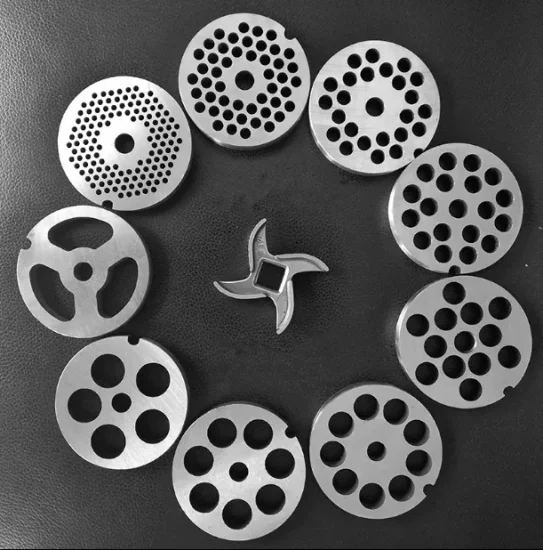

![Aluminum Die Cast Spare Stainless Steel Meat Grinder Knife Plate Food Machine Replacement Powder Industrial Metallurgy Meat Grinder Part Meat Cutting Casting]()

Aluminum Die Cast Spare Stainless Steel Meat Grinder Knife Plate Food Machine Replacement Powder Industrial Metallurgy Meat Grinder Part Meat Cutting Casting

-

![Precision Machining Aluminum Auto Parts by 5 Axis CNC]()

Precision Machining Aluminum Auto Parts by 5 Axis CNC

-

![Custom OEM CNC High Demand Precision Machined Machining Machinery Services Stainless Steel Lathe Turning Miling Aluminum Copper Metal Spare Machining Parts]()

Custom OEM CNC High Demand Precision Machined Machining Machinery Services Stainless Steel Lathe Turning Miling Aluminum Copper Metal Spare Machining Parts